ST HELIER, Jersey, Nov. 11, 2024 (GLOBE NEWSWIRE) — Caledonia Mining Corporation Plc (“Caledonia” or “the Company”) (NYSE AMERICAN: CMCL; AIM: CMCL; VFEX: CMCL) is pleased to announce the first results from its recent exploration program at Motapa, an exploration project acquired in November 2022, located directly adjacent to the Company’s Bilboes Gold Project in southern Zimbabwe.

At Motapa, the combination of diamond drilling (“DD”) and reverse circulation drilling (“RC”), designed to test the continuation of sulphide zones of mineralisation below the historic oxide open pits, have returned highly encouraging results. In addition, shallower drilling in new target areas has returned encouraging results both in shallower oxide, and deeper sulphide zones.

The program to date has achieved the initial objectives and included 12,724m of trenching, 4,143m of DD and 5,433m of RC. The drill program featured generally wide-spaced holes at several prospects on the Motapa lease area and highlighted the presence of widespread gold mineralization over a combined strike length of more than 9km. Results included significant high grade gold mineralization in numerous areas (e.g. in particular the Jupiter, Pluvious and Mpudzi areas) which will now be the focus for follow up drilling with a view to defining an open pit mineral resource. Drilling highlights to date include:

- Hole JPRC01 – 12.00m* at 6.36g/t from 81m downhole, RC

- Hole JPRC05 – 13.00m at 5.17g/t from 88m downhole, RC

- Hole PLVRC06 – 7.00m at 3.27g/t from 64m downhole, RC

- Hole MPZRC02 – 4.00m at 10.95g/t from 12m downhole, RC

- Hole JDD08 – 14.00m at 3.20g/t from 63m downhole, DD

- Hole PLVDD01 – 8.00m at 4.00g/t from 74m downhole, DD

*all intersections above are down hole intersections; estimated true widths, all drill hole intersections are quoted in the tables later in this press release.

Further information on the results is provided below.

Chief Executive Officer, Mark Learmonth, said:

“The results from the sampling at Motapa have delivered encouraging results in terms of strike width, length and grade. The drill program featured generally wide-spaced holes at several prospects on the Motapa lease area and highlighted the presence of widespread gold mineralization over a combined strike length of more than 9 km.

“Motapa sits adjacent to Bilboes, which is where the Company plans to develop a major new high grade open pit gold mine. These initial results confirm that Motapa will continue to form a key role in the Company’s growth strategy.”

Enquiries:

| Caledonia Mining Corporation Plc Mark Learmonth Camilla Horsfall |

Tel: +44 1534 679 800 Tel: +44 7817 841 793 |

| Cavendish Capital Markets Limited (Nomad and Joint Broker) Adrian Hadden Pearl Kellie |

Tel: +44 207 397 1965 Tel: +44 131 220 9775 |

| Panmure Liberum Limited (Joint Broker) Scott Mathieson Matt Hogg |

Tel: +44 20 3100 2000 |

| Camarco, Financial PR (UK) Gordon Poole Julia Tilley Elfie Kent |

Tel: +44 20 3757 4980 |

| 3PPB (Financial PR, North America) Patrick Chidley Paul Durham |

Tel: +1 917 991 7701 Tel: +1 203 940 2538 |

| Curate Public Relations (Zimbabwe) Debra Tatenda |

Tel: +263 77802131 |

| IH Securities (Private) Limited (VFEX Sponsor – Zimbabwe) Lloyd Mlotshwa |

Tel: +263 (242) 745 119/33/39 |

Overview of Motapa Exploration Program

- The Motapa exploration program commenced in 2023 with geological mapping, geophysical surveys, trenching, and a later program in 2024 of surface exploration drilling.

- The initial work informed targets for wide spaced drilling to test mineralization below the historically mined oxide open pits and in new target areas which have not yet been mined.

- To date, 12,724m of trenching, 4,143m of DD and 5,433m of RC have been completed, marking the end of the 2024 exploration drilling activities.

- To date, complete data (assay results) have been received for 93% of DD samples and 61% of RC samples submitted for analysis at external laboratories. A total of 13,374 trench samples have been analyzed by means of bottle roll analysis at the Company’s internal laboratory at Bilboes.

- Caledonia believes that the property presents substantial upside from both greenfield and brownfield exploration opportunities.

- Further updates will be provided on the completion and assessment of the outstanding assay results.

Details of the Program

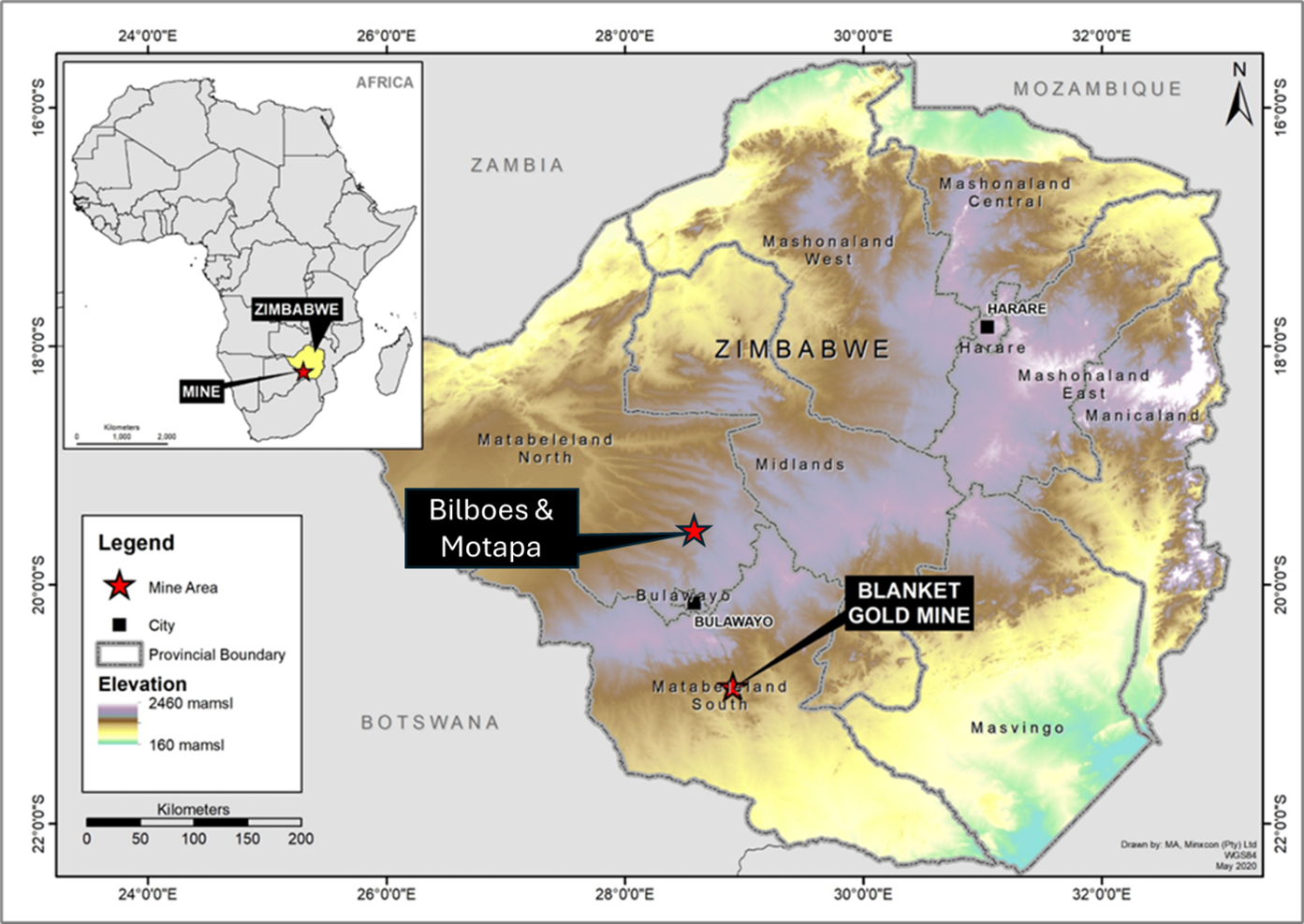

Motapa is located approximately 110km north of Bulawayo in the Bubi District of the Matabeleland North Province of Zimbabwe. The tenement is within state land under the jurisdiction of the Bubi Rural District and the tenure is held in the form of a mining lease covering approximately 2,200 hectares which provides for both exploration and mining rights. The locality of Motapa is shown relative to other key Caledonia properties in Figure 1. Caledonia’s Bilboes property and associated large scale new development project is located directly to the north of Motapa with Bilboes and Motapa sharing a lease boundary.

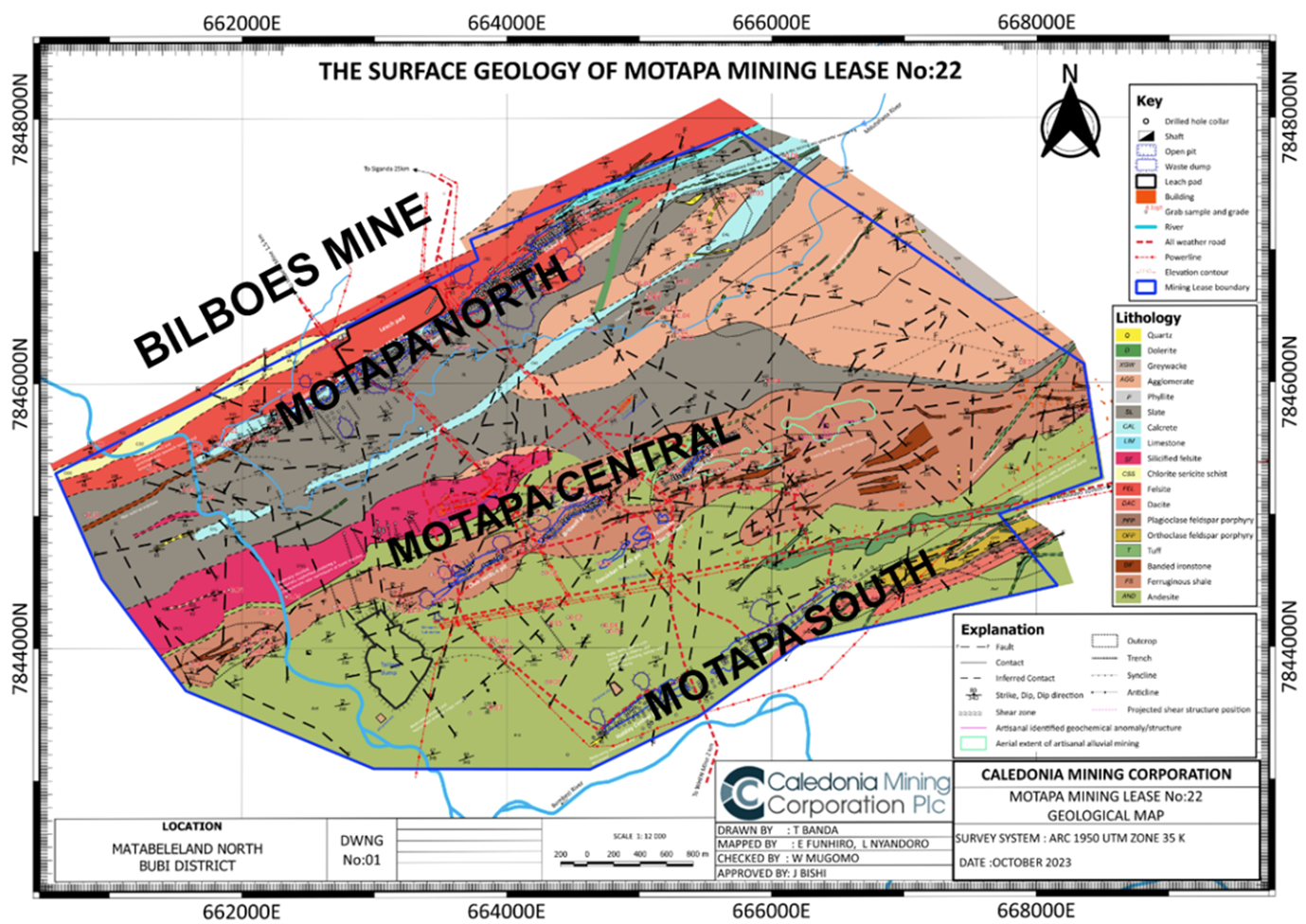

The mining lease area is part of the Bubi Greenstone Belt and occupies a ± 6km stretch of an elongated northeast – southwest trending intensely sheared broad shear zone with three main mineralised footprints. Named from the north, these shear structures are Motapa North, Motapa Central and Motapa South (Figure 2).

Figure 1: General Locality of the Motapa Exploration Project, Zimbabwe.

Figure 2: Surface Geology and Main Shear Zones at the Motapa Exploration Project.

(Refer to Figure 3 for precise extent of the mining lease boundary.)

Caledonia believes that the property presents both greenfield and brownfield upside exploration opportunities, and the proximity to the planned development at Bilboes makes Motapa strategically very important for Caledonia, given the potential synergies between the two.

Initial exploration activities at Motapa commenced in 2023 and comprised the following:

- Detailed geological mapping of the tenement

- Historical data collation of previous exploration and mining activities

- Aero-magnetics flown by drone

- Ground penetrating radar (LOZA) surveys to identify underground voids

These activities, completed in the same calendar year, were used to define an exploration program for 2024. The total exploration works program originally planned comprised the following:

- 22,212 meters of surface trenching

- 3,987 meters of DD, 3,502 samples submitted of which 3,268 assays have been received.

- 4,663 meters of RC, 4,226 samples submitted of which 2,575 assays have been received.

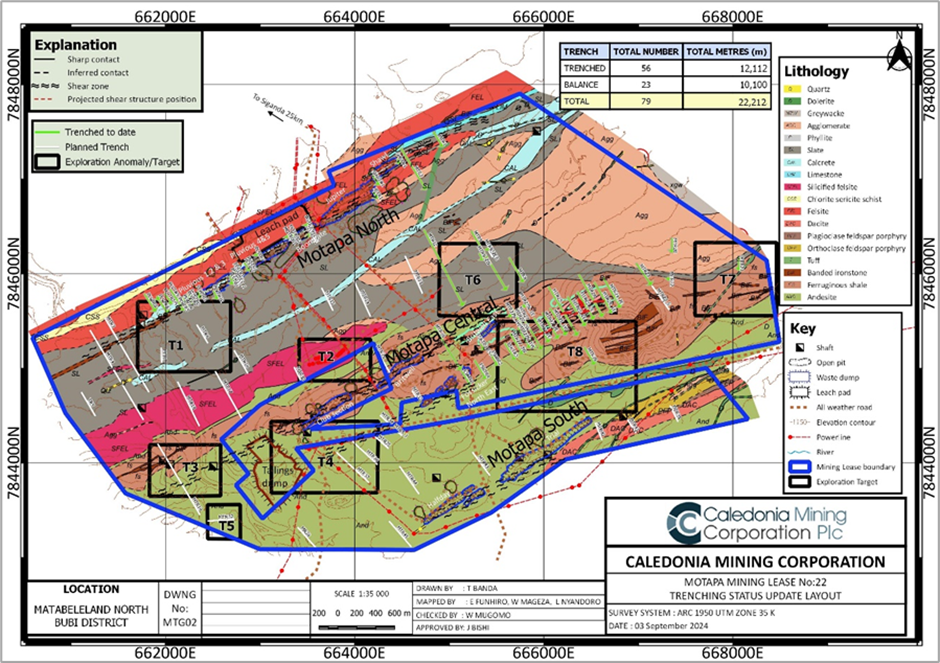

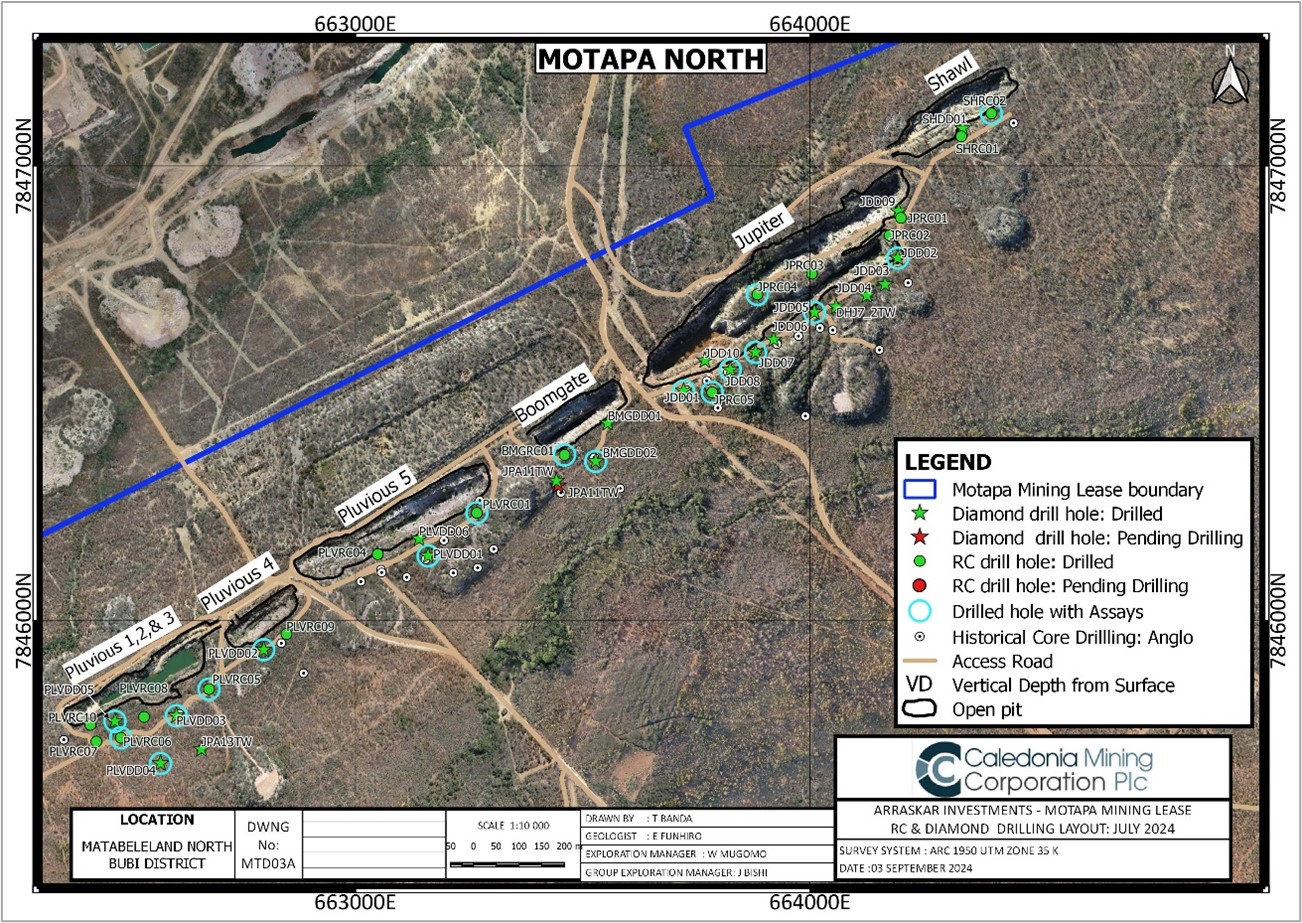

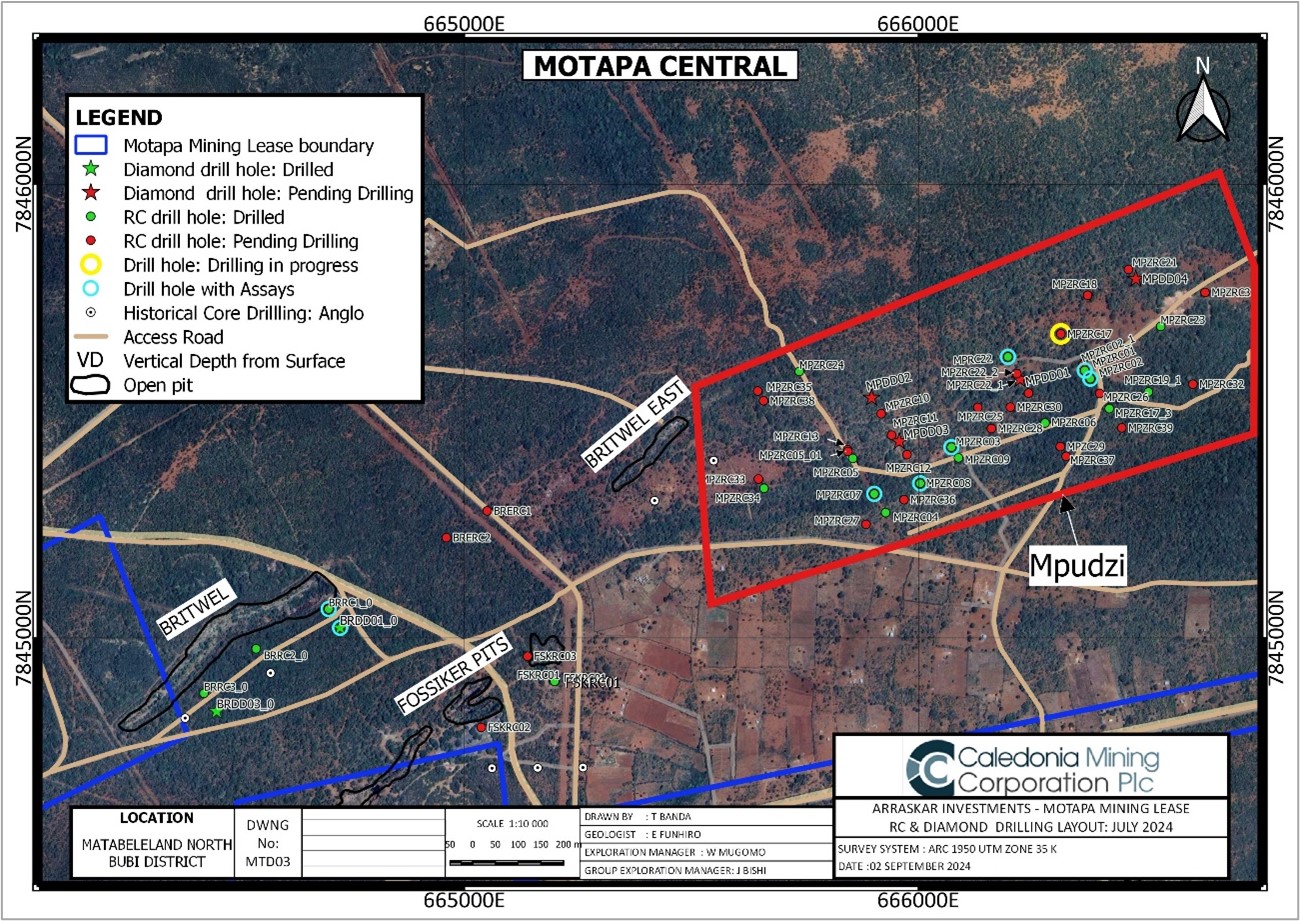

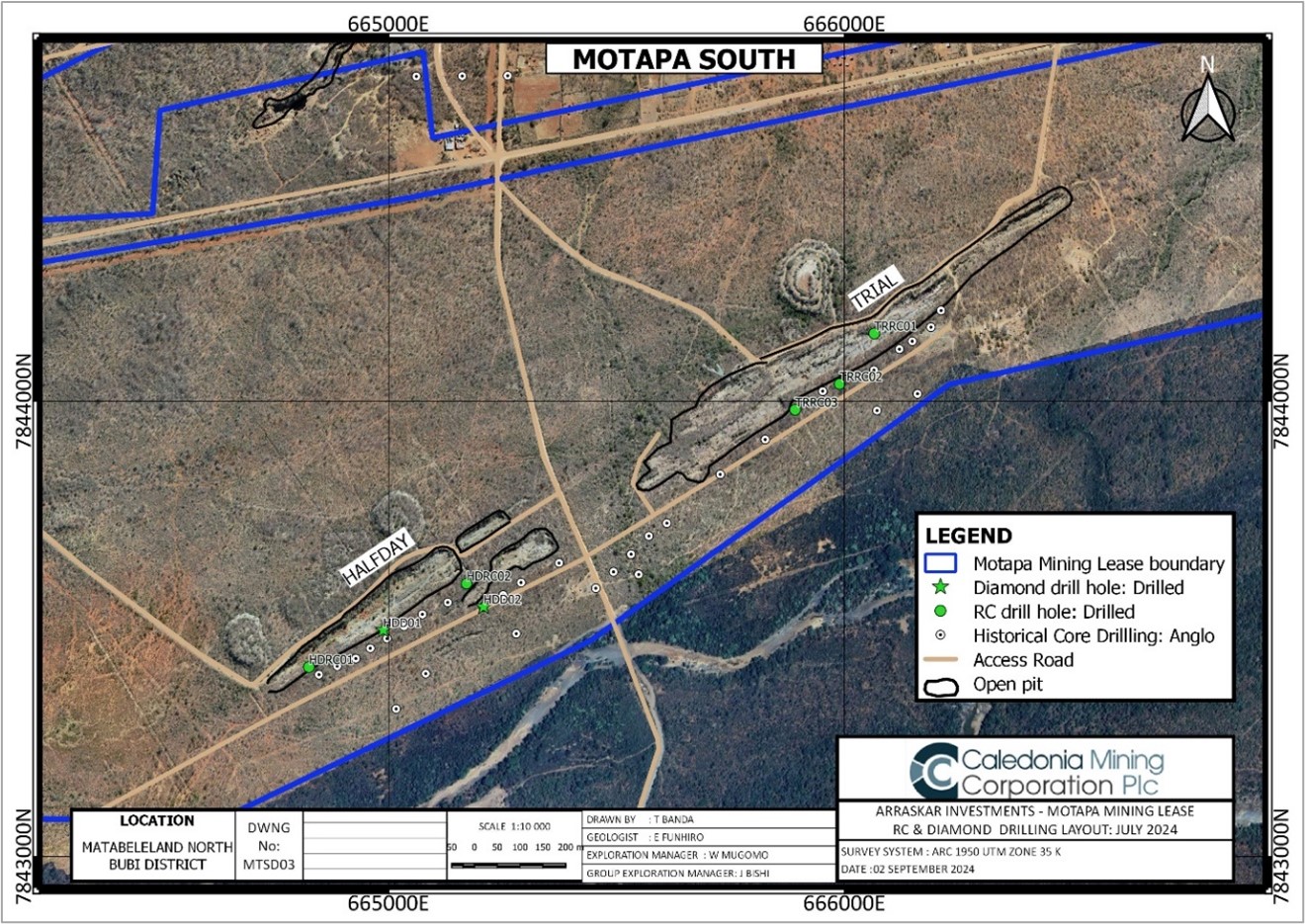

To date, 12,724m of trenching, 4,143m of DD and 5,433m of RC have been completed, marking the end of the 2024 exploration drilling activities. Figure 3 shows approximate locations of trenching sites, while Figures 4, 5 and 6 are air photos showing the North, Central and South known mineralized trends on Motapa, in relation to old workings with drill hole locations marked.

To date, complete data (assay results) have been received for 93% of DD samples and 61% of RC samples submitted for analysis at external laboratories. A total of 13,374 trench samples have been analyzed by means of bottle roll analysis at the Company’s internal laboratory at Bilboes.

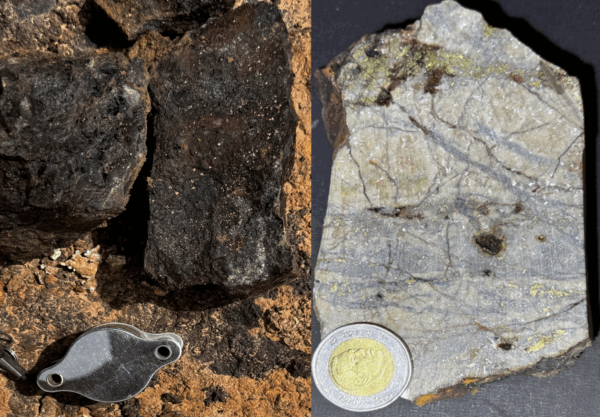

Trenching and infill mapping identified Slates, Meta-andesites and BIFs as host rocks to gold mineralization. Gold mineralization is associated with extensive sericite, carbonate, silica, pyrite, arsenopyrite and magnetite alteration. From logging of RC and DD drill hole core, it is evident that mineralization is predominantly structurally controlled and associated with intense shearing, silicification and sulphidisation (pyrite and arsenopyrite) in slates, quartz feldspar porphyries (Motapa North) and Meta-Andesites and BIF (Motapa Central and South). Sporadic decent widths (+5m), high-grade zones are mostly ascribed to Motapa North Jupiter and Shawl orebodies, with the widest zone encountered being 12.04m at 3.20g/t at Jupiter.

Trenching and drilling methodology and results are discussed in sections later on in this document.

Key Conclusions Regarding Work to Date

Motapa North

The historic oxide open pits are located approximately 250 meters to the south of the shared Bilboes property boundary and a few hundred meters further to the planned metallurgical facility at Bilboes. Exploration drilling during 2024 was focused more on the northern trend which has returned sufficiently encouraging results to warrant further follow up drilling during 2025. The focus of further drilling will be to define an open pit mineral resource in the near term along the 2,750-meter strike length of Motapa North with drill section lines planned at a 25 meter spacing.

Motapa Central

Historically, underground mining took place in the western portion of Motapa Central along the Club section. Underground working and assay plans show that highly encouraging grades were mined in the past, and therefore exploration drilling has been focused on the eastern portion in the Mpudzi section.

The Mpudzi section has no historical open pits and exploration drilling encountered shallow high grade mineralisation with deeper drill holes showing the continuation of these zones at depth. The shallow mineralisation appears to be oxidised and further drilling with the aim to define a near-term oxide mineral resource is planned for 2025.

Motapa South

Limited drillholes were planned and executed at Motapa South due to both the north and central areas taking precedence because of their proximity to Bilboes. Going forward for 2025, limited drilling will take place with drilling to intensify during 2026 and 2027.

Figure 3: Trenching Localities at the Motapa Exploration Project.

Figure 4: Motapa North strike DD and RC drillhole collars.

Figure 5: Motapa Central strike DD and RC drillhole collars.

Figure 6: Motapa South strike DD and RC drillhole collars.

Clarification of mining lease area

During the Motapa drilling project, a discrepancy was discovered between the mining area noted in the registered mining lease (2,224 hectares) and a historic map of the area by the Surveyor General which was supposed to have informed the extent of the lease (2,161 hectares). Management’s view is that the excluded area has no implications on the ongoing exploration project as there were no plans to explore there and it is not material to Motapa’s development plans. Furthermore, the exclusion of the old tailings dump has reduced the Company’s rehabilitation liability in respect of Motapa.

In summary, the Surveyor General’s map excludes an access road through the area, an old tailings dump and small parts of pits in the central strike zone of the area (see Figure 3 for more detail). The Ministry of Mines has been contacted to resolve the discrepancy and it is likely that the lease will be updated in due course to clarify that the excluded area is not part of the lease, given that the Surveyor General’s map is likely to take precedence.

Trenching and trench sampling methodology

After the geologist has noted that the trench has successfully been excavated to bedrock, the sample intervals are set out on the side walls. At the start of the sample line, a peg is installed into the floor with the trench number. A clean, exposed side of the trench is chosen and maintained throughout the sampling process. The sidewall is cleaned with a shovel to ensure an uncontaminated face is exposed for sampling. Thereafter sample localities are marked on the sidewall.

Sampling is done at one-meter intervals respecting lithological contacts, alterations and structures. A minimum sampling width of 0.3m and maximum of 1m are observed throughout the sample interval marking. A clean sample mat is placed on the floor of the trench and samples are chipped from the bedrock sidewall into a sample pan. Samples are ticketed and placed in a sample bag closed with twine. Sample tickets, locality and weights are recorded on the sample sheet record for each trench.

A total of 15% per batch consists of check samples comprising one standard, one field duplicate and one blank (Dolerite Dyke). Each batch contains a total of 20 samples inclusive of check samples. Trench samples are assayed on site by means of a bottle roll assay at the Company’s Isabella laboratory situated at Bilboes.

Samples above a cut-off grade of 0.10g/t bottle roll grade are selected for fire assay. These samples are composited and sent for analysis at an external laboratory.

The compositing of samples is guided by lithology as well as alteration domains; no sampling will be done across different domains. Outliers with anomalously high grades are not composited unless they are part of a homogenous lithological and alteration domain. When compositing in wider ore zones, a composite sample is made by combining five samples, whilst in narrow ore zones two samples will make up a composite sample. The homogenized sample is split using a riffle splitter to get two 2kg samples to be delivered to the external laboratory for bottle roll analysis and the other for fire assay.

Total meters trenched to date amount to 12,724m, with 13,374 samples being collected from 56 trenches (see Figure 3). Of these samples, 907 samples were selected for fire assay at an external laboratory with results received for 710 samples to date. The longest trench was MTR12 with 894m. The trenches were approximately 0.5-2m deep, were sampled on an individual basis and provided exposures for geological mapping.

Using a 0.1 g/t gold lower cut-off, for the 16 trenches with analytical results (16 of 53), 10 trenches (63%) intersected mineralization. Trenches that intersected gold mineralization are summarized in Table 1. The widest zone of mineralization encountered was 19.32m at 0.36 g/t (MTR25A) with a peak value of 11.75 g/t. However, most of the mineralization widths are pervasively narrow.

Widely spaced trenches (100m) MTR27, MTR27_1E, MTR27_2E and MTR25 have suggested a continuity of mineralization over a 250m strike length. Mineralization has also been encountered in trench MTR9 in anomalies located along Motapa Central strike.

Trenching and infill mapping is highlighting increased recognition of slates, andesites and BIF lithologies as host rocks to gold mineralization. Gold mineralization is associated with extensive sericite, carbonate, silica, pyrite and/or magnetite alteration. Drill testing of the priority targets is in progress.

Surface drilling

Sixty-two down-the-hole surveys were conducted on RC and DD holes which showed no major departures from the planned trajectory. The project QAQC statistical tests carried out on DD and RC assay results from the ISO accredited Performance Laboratories were satisfactory at an overall pass rate of 90%.

The RC and DD methodology is discussed below with the results obtained tabulated in Table 5 and the drill hole information tabulated in Table 6. Drill hole localities for Motapa North, Motapa Central and Motapa South are provided in Figure 5 and Figure 6 respectively.

DD methodology

After all geotechnical and structural logging is complete, the geologist inspects the core and delineates potential ore zones.

The geologist determines sampling depths, each sampling interval depending on lithological contacts, alterations, structures and quantity of sulphides with the maximum sampling width of 1m and minimum sampling width of 0.3m. The sample depths are printed on a sampling sheet and need to be marked on the core before density determination can take place. The densities are measured before the core is cut. Sampling starts five meters away from the footwall contact and ends five meters away from the hanging wall contact to allow for sterilization.

Half core was sampled, with the other half remaining at the core shed for archiving.

Core segments were picked within demarcated and labeled intervals and put in respective sample bags. The samples are numbered as per the sampling plan with one ticket put into the respective sample bag, and the other onto the remaining piece of core where the sample would have been collected. The sample I.D.is also scribbled on the remaining half core.

At the end, sample bags are sealed with cable ties and weighed; with sample weights recorded on the sampling sheet.

The samples are then bagged into grain bags for dispatch to an outside accredited laboratory or storage prior to submission.

RC methodology

Checks for rig outlet and splitter cleanliness are conducted prior to the commencement of drilling activities and continuously throughout the drilling activities to avoid sample contamination.

Sample bags are pre-numbered with unique sample numbers (drill hole number and drill hole depth intervals) before the drilling commences. Sample depths recorded are relative to the ground surface at the drillhole collar. If no sample is recovered, such as when voids are intersected, the numbering sequence is continued uninterrupted with empty numbered bags inserted into the sample sequence. This will avoid possible confusion in sampling. Sample bags are immediately sealed to effectively prevent external contamination.

A sample bag is tied to the sample outlet of the rig in preparation for sample collection before sampling commences. Bulk samples are collected at 1m intervals and split using a riffle splitter to three samples. One sub-sample of 2kg will be taken to the lab for assaying, the second remains as a field duplicate for storage at the core shed and the third is prepared as chips for traying. The sampling crew will sample at the designated (one meter) intervals down the hole. The geologist verifies the intervals from the driller’s marks on the mast or pull-down chain. For samples sent to the laboratory, the sampling quality is monitored continuously as the geologist ensures the samples for QA & QC monitoring purposes are inserted in each sampling stream batch of 20 samples with CRMs being alternated from batch to batch from low, medium and high grade.

QAQC Procedures

For DD samples, a train comprising a single blank, CRM, LCR, and LPR reference sample is inserted into a batch of 20 samples. This process is repeated until the entire drillhole is completed with the CRMs being alternated from batch to batch (low, medium and high grade).

For RC samples, a train comprising a single blank, CRM, FDUP, and LPR reference sample is inserted into a batch of 20 samples. This process is repeated until the entire drillhole is completed with the CRMs being alternated from batch to batch (low, medium and high grade).

For trench sampling, a train comprising a single blank, CRM and FDUP reference sample is inserted into a batch of 20 samples. This process is repeated until the entire trench is completed with the CRMs being alternated from batch to batch (low, medium and high grade).

Every sampling sequence starts with a blank sample and ends with a blank sample. Analytical results for blanks, standards and duplicates are graphed and, if any fail, the entire batch is re-assayed. Batches that passed the QAQC graphs are then captured in the database. QAQC is monitored continuously. All assays sent to an external laboratory refer to Performance Laboratories, an accredited laboratory in Zimbabwe.

Overall QAQC compliance rate of 90% is comprised as per Table 1 below. Table 1: QAQC Results from DD and RC Drilling Activities

| QAQC Insertion | % Insertion | Pass / Fail | # of Samples |

% | Comments | ||

| FDUP Duplicates | 2 | % | Pass | 108 | 98 | % | Good correlation of R²=0.89 |

| Fail | 2 | 2 | % | ||||

| Total | 110 | ||||||

| LCR Duplicates | 3 | % | Pass | 137 | 82 | % | Poor correlation, could be due to nugget effect. |

| Fail | 30 | 18 | % | ||||

| Total | 167 | ||||||

| LPR Duplicates | 4 | % | Pass | 204 | 91 | % | Satisfactory correlation. |

| Fail | 21 | 9 | % | ||||

| Total | 223 | ||||||

| CRMs | 5 | % | Pass | 213 | 77 | % | Most failures are on a high-grade CRM of 12g/t. All failed batches being sent for re-analysis at the lab’s cost. |

| Fail | 60 | 22 | % | ||||

| Total | 276 | ||||||

| Blanks | 6 | % | Pass | 288 | 99 | % | Good QAQC. Failed batches being re-analysed |

| Fail | 3 | 1 | % | ||||

| Total | 291 | ||||||

| Grand Total | 20 | % | Pass | 955 | 90 | % | Satisfactory Compliance Rate |

| Fail | 116 | 11 | % | ||||

| Total | 1067 | ||||||

Table 1: QAQC Results from DD and RC Drilling Activities

FDUP – Field Duplicate, LCR – lab coarse repeat, LPR – lab pulp repeat, CRM – Certified Reference Material, Blank – Dolerite Dyke

In addition to the QAQC protocol above, a check laboratory and umpire laboratory are utilized to validate the results from the principal laboratory. Zimlabs is used as a check laboratory with 10% of assays re-assayed. Antech Laboratories is used as an umpire laboratory with 5% of assays re-assayed. Correlation between the Performance and Antech laboratories is excellent with Zimlabs showing less of a correlation.

Qualified person

Craig James Harvey, MGSSA, MAIG, Caledonia Vice President, Technical Services, has reviewed and approved the scientific and technical information contained in this news release. Craig James Harvey is a “Qualified Person” as defined by each of (i) the Canadian Securities Administrators’ National Instrument 43-101 – Standards of Disclosure for Mineral Projects and (ii) subpart 1300 of Regulation S-K.

Note:

This announcement contains inside information which is disclosed in accordance with the Market Abuse Regulation (EU) No. 596/2014 (“MAR”) as it forms part of UK domestic law by virtue of the European Union (Withdrawal) Act 2018 and is disclosed in accordance with the Company’s obligations under Article 17 of MAR.

Appendix

Highlights from the DD and RC campaigns are provided in the tables below. [A full overview is included in the appendix]:

| RC Highlights | ||||||||

| Holes Identifier |

Orebody Name |

Orebody Intersection |

Core Length (m) |

True width (m) |

Grade (g/t) |

Orebody Intersection depth from surface(m) |

E.O.H (m) | |

| From (m) | To (m) | |||||||

| JPRC01 | JUPITER | 81.00 | 93.00 | 12.00 | 9.72 | 6.36 | 67.93 | 110 |

| JPRC05 | JUPITER | 88.00 | 101.00 | 13.00 | 10.53 | 5.17 | 76.21 | 160 |

| PLVRC06 | PLUVIOUS 1,2&3 | 64.00 | 71.00 | 7.00 | 6.62 | 3.27 | 53.68 | 150 |

| MPZRC02 | MPUDZI | 12.00 | 16.00 | 4.00 | 3.86 | 10.95 | 8.00 | 55 |

| 36.00 | 39.00 | 3.00 | 2.89 | 2.83 | 25.00 | |||

Table 2: RC Drilling Highlights

| DD Highlights | ||||||||

| Holes Identifier |

Orebody Name |

Orebody Intersection |

Core Length (m) |

True width (m) |

Grade (g/t) |

Orebody Intersection depth from surface(m) |

E.O.H (m) | |

| From (m) | To (m) | |||||||

| JDD08 | JUPITER | 63.00 | 77.00 | 14.00 | 12.04 | 3.20 | 44.6 | 200 |

| PLVDD01 | PLUVIOUS 5 | 74.00 | 82.00 | 8.00 | 6.94 | 4.00 | 57.5 | 170 |

| PLVDD02 | PLUVIOUS 4 | 64.00 | 66.00 | 2.00 | 1.75 | 4.04 | 50.4 | 149 |

| PLVDD04 | PLUVIOUS 1,2&3 | 137.00 | 142.00 | 5.00 | 4.80 | 3.31 | 114.9 | 248 |

Table 3: DD Drilling Highlights

The following tables below provide the full results

| Exploration Anomaly/Target | Trench ID | Trench Start | Trench End | Azimuth (°) | Trench length (m) | Intersection | True width (m) | Grade(g/t) | |||||

| Easting | Northing | Elevation | Easting | Northing | Elevation | From | To | ||||||

| T1 | PLVTR5.5 | 661984 | 7845794 | 1122 | 662073 | 7845680 | 1124 | 142 | 149 | 71.00 | 72.00 | 0.97 | 0.30 |

| Shawl | SHWTR1 | 664186 | 7847041 | 1141 | 664262 | 7846934 | 1148 | 144 | 132 | 43.00 | 46.00 | 2.90 | 0.35 |

| 73.00 | 74.00 | 0.97 | 0.32 | ||||||||||

| Jupiter East | JETR1 | 664195 | 7846870 | 1145 | 664246 | 7846791 | 1148 | 147 | 115 | 24.00 | 25.00 | 0.97 | 0.29 |

| Shawl East | MTR1 | 664823 | 7847517 | 1155 | 664940 | 7847336 | 1147 | 147 | 216 | 64.00 | 66.00 | 1.93 | 0.69 |

| 102.00 | 103.00 | 0.97 | 0.17 | ||||||||||

| MTR2 | 664487 | 7847329 | 1149 | 664764 | 7846876 | 1141 | 149 | 531 | 82.00 | 83.00 | 0.97 | 0.34 | |

| 90.00 | 94.00 | 3.86 | 0.29 | ||||||||||

| T6 | MTR12 | 664732 | 7846468 | 1106 | 665141 | 7845671 | 1145 | 153 | 894 | 56.00 | 57.00 | 0.97 | TBA |

| 263.00 | 264.00 | 0.97 | |||||||||||

| 316.00 | 317.00 | 0.97 | |||||||||||

| 533.00 | 534.00 | 0.97 | |||||||||||

| 866.00 | 867.00 | 0.97 | |||||||||||

| MTR9 | 665277 | 7846381 | 1133 | 665613 | 7845816 | 1146 | 149 | 663 | 193.00 | 194.50 | 1.45 | 0.51 | |

| 216.00 | 217.00 | 0.97 | 2.61 | ||||||||||

| 217.00 | 219.00 | 1.93 | 0.42 | ||||||||||

| MTR9W | 665301 | 7846243 | 1139 | 665365 | 7846136 | 1140 | 149 | 126 | NSI | ||||

| MTR8 | 665634 | 7846172 | 1144 | 665792 | 7845905 | 1149 | 149 | 311 | NSI | ||||

| T8 | MTR27 | 665723 | 7845630 | 1152 | 665982 | 7845196 | 1173 | 149 | 511 | 12.00 | 16.00 | 3.86 | 0.56 |

| 210.30 | 212.00 | 1.64 | 0.20 | ||||||||||

| 229.00 | 231.00 | 1.93 | 0.44 | ||||||||||

| 262.00 | 265.30 | 3.19 | 1.01 | ||||||||||

| 297.00 | 298.00 | 0.97 | 0.83 | ||||||||||

| MTR25 | 666048 | 7845866 | 1153 | 666216 | 7845585 | 1171 | 149 | 329 | 275.00 | 277.00 | 1.93 | 0.37 | |

| 286.00 | 288.00 | 1.93 | 0.17 | ||||||||||

| 294.00 | 295.20 | 1.16 | 0.52 | ||||||||||

| 296.40 | 296.70 | 0.29 | 11.75 | ||||||||||

| 296.70 | 297.20 | 0.48 | 1.12 | ||||||||||

| 297.20 | 298.80 | 1.55 | 0.23 | ||||||||||

| 311.00 | 314.30 | 3.19 | 0.14 | ||||||||||

| 315.00 | 316.00 | 0.97 | 0.25 | ||||||||||

| 319.00 | 321.00 | 1.93 | 1.04 | ||||||||||

| 321.00 | 323.00 | 1.93 | 0.70 | ||||||||||

| 323.00 | 323.30 | 0.29 | 10.41 | ||||||||||

| MTR25A | 666225 | 7845592 | 1171 | 666233 | 7845574 | 1172 | 154 | 20 | 0.00 | 20.00 | 19.32 | 0.36 | |

| MTR25B | 666224 | 7845571 | 1174 | 666366 | 7845333 | 1179 | 149 | 279 | 0.00 | 8.00 | 7.73 | 0.20 | |

| 122.00 | 123.00 | 0.97 | 0.11 | ||||||||||

| 123.00 | 124.00 | 0.97 | 1.54 | ||||||||||

| 124.00 | 125.00 | 0.97 | 0.20 | ||||||||||

| 125.00 | 126.00 | 0.97 | 7.26 | ||||||||||

| MTR25C | 666341 | 7845318 | 1177 | 666351 | 7845287 | 1180 | 161 | 33 | NSI | ||||

| MTR26 | 666421 | 7845239 | 1185 | 666543 | 7845034 | 1179 | 149 | 237 | NSI | ||||

| MTR24 | 666369 | 7845997 | 1160 | 666625 | 7845540 | 1208 | 151 | 530 | 314.40 | 315.00 | 0.58 | TBA | |

| 318.00 | 320.00 | 1.93 | |||||||||||

| 335.00 | 336.00 | 0.97 | |||||||||||

| 340.00 | 341.00 | 0.97 | |||||||||||

| 344.00 | 345.00 | 0.97 | |||||||||||

| 352.00 | 354.00 | 1.93 | |||||||||||

| 381.00 | 382.00 | 0.97 | |||||||||||

| MTR27_1E | 665893 | 7845536 | 1164 | 666059 | 7845271 | 1171 | 148 | 314 | 87.00 | 89.00 | 1.93 | 0.12 | |

| 114.00 | 115.00 | 0.97 | 0.19 | ||||||||||

| 179.00 | 181.00 | 1.93 | 0.26 | ||||||||||

| 189.00 | 192.00 | 2.90 | 0.24 | ||||||||||

| 195.00 | 198.00 | 2.90 | 0.15 | ||||||||||

| 202.00 | 203.50 | 1.45 | 0.16 | ||||||||||

| 210.00 | 212.00 | 1.93 | 0.11 | ||||||||||

| MTR27_2E | 665985 | 7845590 | 1158 | 666158 | 7845307 | 1170 | 149 | 333 | 83.00 | 84.00 | 0.97 | 0.30 | |

| 141.00 | 142.00 | 0.97 | 0.11 | ||||||||||

| 177.00 | 188.00 | 10.63 | 0.37 | ||||||||||

| MTR27_1W | 665724 | 7845432 | 1167 | 665858 | 7845210 | 1175 | 149 | 261 | NSI | ||||

| MTR27_2W | 665642 | 7845374 | 1166 | 7845164 | 665769 | 1169 | 149 | 246 | 2.00 | 3.00 | 0.97 | TBA | |

| 3.00 | 4.00 | 0.97 | |||||||||||

| 12.00 | 13.00 | 0.97 | |||||||||||

| 14.00 | 15.00 | 0.97 | |||||||||||

| 25.00 | 27.00 | 1.93 | |||||||||||

| 30.00 | 31.00 | 0.97 | |||||||||||

| 33.00 | 35.00 | 1.93 | |||||||||||

| 39.00 | 40.00 | 0.97 | |||||||||||

| 41.00 | 42.00 | 0.97 | |||||||||||

| MTR27N_1W | 665636 | 7845576 | 1153 | 7845538 | 665659 | 1156 | 150 | 45 | 0.00 | 1.00 | 0.97 | ||

| 3.00 | 4.00 | 0.97 | |||||||||||

| 6.00 | 15.00 | 8.69 | |||||||||||

| 17.00 | 18.00 | 0.97 | |||||||||||

| MTR27N_1E | 665783 | 7845679 | 1151 | 7845640 | 665807 | 1152 | 150 | 47 | NSI | ||||

| MTR25_1W | 666065 | 7845640 | 1157 | 666243 | 7845343 | 1171 | 149 | 350 | 51.00 | 52.00 | 0.97 | TBA | |

| 110.00 | 110.50 | 0.48 | |||||||||||

| 114.00 | 115.00 | 0.97 | |||||||||||

| 125.00 | 126.00 | 0.97 | |||||||||||

| 130.00 | 131.00 | 0.97 | |||||||||||

| 134.00 | 135.00 | 0.97 | |||||||||||

| 311.00 | 312.00 | 0.97 | |||||||||||

| MTR25_1E | 666251 | 7845761 | 1166 | 666443 | 7845442 | 1184 | 149 | 375 | 60.00 | 63.00 | 2.90 | ||

| 64.00 | 68.00 | 3.86 | |||||||||||

| 72.00 | 73.00 | 0.97 | |||||||||||

| 76.00 | 77.00 | 0.97 | |||||||||||

| 93.00 | 99.00 | 5.80 | |||||||||||

| 161.00 | 162.00 | 0.97 | |||||||||||

| 166.00 | 227.00 | 58.92 | |||||||||||

| 235.00 | 236.00 | 0.97 | |||||||||||

| 237.00 | 245.00 | 7.73 | |||||||||||

| 250.00 | 251.00 | 0.97 | |||||||||||

| 253.00 | 254.00 | 0.97 | |||||||||||

| 261.00 | 262.00 | 0.97 | |||||||||||

| MTR25_2E | 666353 | 7845814 | 1171 | 666532 | 7845514 | 1198 | 149 | 353 | 46.00 | 47.00 | 0.97 | ||

| 87.00 | 88.00 | 0.97 | |||||||||||

| 109.00 | 110.00 | 0.97 | |||||||||||

| 249.00 | 252.00 | 2.90 | |||||||||||

| 270.00 | 271.00 | 0.97 | |||||||||||

| 274.00 | 275.00 | 0.97 | |||||||||||

| 277.00 | 279.00 | 1.93 | |||||||||||

| 296.00 | 297.00 | 0.97 | |||||||||||

| MTR24_1E | 666533 | 7845916 | 1175 | 666720 | 7845590 | 1209 | 150 | 382 | 126.00 | 127.00 | 0.97 | ||

| 161.00 | 163.00 | 1.93 | |||||||||||

| 166.00 | 167.00 | 0.97 | |||||||||||

| MTR24_2E | 666626 | 7845968 | 1169 | 666815 | 7845638 | 1199 | 150 | 385 | 147.00 | 148.00 | 0.97 | ||

| FSKTR1 | 665143 | 7844949 | 1163 | 665225 | 7844819 | 1158 | 148 | 155 | 0.00 | 5.00 | 4.83 | ||

| 6.00 | 9.00 | 2.90 | |||||||||||

| 10.00 | 14.00 | 3.86 | |||||||||||

| 17.00 | 18.00 | 0.97 | |||||||||||

| 19.00 | 21.00 | 1.93 | |||||||||||

| 22.00 | 37.00 | 14.49 | |||||||||||

| 39.00 | 53.00 | 13.52 | |||||||||||

| 54.00 | 56.00 | 1.93 | |||||||||||

| 57.00 | 58.00 | 0.97 | |||||||||||

| 59.00 | 60.00 | 0.97 | |||||||||||

| 61.00 | 77.00 | 15.45 | |||||||||||

| 78.00 | 79.00 | 0.97 | |||||||||||

| 83.00 | 84.00 | 0.97 | |||||||||||

| 89.00 | 90.00 | 0.97 | |||||||||||

| 93.00 | 98.00 | 4.83 | |||||||||||

| 101.00 | 108.00 | 6.76 | |||||||||||

| 109.00 | 110.00 | 0.97 | |||||||||||

| 112.00 | 114.00 | 1.93 | |||||||||||

| 134.00 | 135.00 | 0.97 | |||||||||||

| FSKTR4 | 665267 | 7845089 | 1167 | 665292 | 7845048 | 1165 | 149 | 49 | NSI | ||||

| FSKTR4A | 665295 | 7845042 | 1164 | 665310 | 7845016 | 1163 | 149 | 31 | |||||

| FSKTR4B | 665312 | 7845014 | 1164 | 665316 | 7845007 | 1164 | 152 | 8 | |||||

| FSKTR4C | 665322 | 7844999 | 1163 | 665328 | 7844988 | 1162 | 149 | 14 | |||||

| FSKTR4D | 665334 | 7844978 | 1162 | 665351 | 7844949 | 1160 | 149 | 35 | |||||

| FSKTR4E | 665356 | 7844952 | 1160 | 665360 | 7844943 | 1160 | 157 | 12 | |||||

| FSKTR4F | 665356 | 7844940 | 1160 | 665364 | 7844928 | 1159 | 147 | 15 | |||||

| FSKTR4G | 665367 | 7844924 | 1158 | 665378 | 7844906 | 1158 | 149 | 22 | |||||

| FSKTR4H | 665383 | 7844897 | 1157 | 665390 | 7844886 | 1157 | 148 | 14 | |||||

| FSKTR2 | 665434 | 7845158 | 1163 | 665469 | 7845101 | 1161 | 148 | 68 | |||||

| FSKTR2A | 665470 | 7845099 | 1161 | 665474 | 7845093 | 1161 | 147 | 7 | |||||

| FSKTR2B | 665476 | 7845095 | 1161 | 665489 | 7845078 | 1160 | 142 | 22 | |||||

| FSKTR2C | 665486 | 7845074 | 1160 | 665514 | 7845027 | 1158 | 149 | 56 | |||||

| FSKTR3 | 665574 | 7845290 | 1165 | 665622 | 7845214 | 1167 | 148 | 91 | |||||

| FSKTR3A | 665630 | 7845199 | 1167 | 665657 | 7845155 | 1165 | 149 | 51 | 2.00 | 3.00 | 0.97 | TBA | |

| FSKTR3B | 665664 | 7845143 | 1164 | 665700 | 7845086 | 1163 | 148 | 67 | NSI | ||||

| FSKTR2 EXT | 665328 | 7845260 | 1164 | 665375 | 7845192 | 1167 | 145 | 83 | 2.00 | 3.00 | 0.97 | TBA | |

| 5.00 | 6.00 | 0.97 | |||||||||||

| 9.00 | 10.00 | 0.97 | |||||||||||

| 16.00 | 18.00 | 1.93 | |||||||||||

| 21.00 | 22.00 | 0.97 | |||||||||||

| 27.00 | 27.50 | 0.48 | |||||||||||

| Mpudzi East | MTR23 | 666917 | 7846195 | 1164 | 667141 | 7845878 | 1177 | 145 | 391 | NSI | |||

| MTR22 | 667320 | 7845967 | 1179 | 667321 | 7845922 | 1182 | 180 | 46 | |||||

| MTR20 | 667356 | 7846381 | 1160 | 667357 | 7846217 | 1165 | 180 | 165 | |||||

| MTR21 | 668061 | 7846182 | 1177 | 668062 | 7846029 | 1182 | 180 | 154 | |||||

| Boomgate | MOTR002 | 663329 | 7846428 | 1140 | 663354 | 7846383 | 1138 | 152 | 52 | ||||

| MOTR001 | 663284 | 7846397 | 1140 | 663299 | 7846375 | 1139 | 148 | 28 | |||||

| BGTR2_0 | 663490 | 7846524 | 1139 | 663500 | 7846496 | 1139 | 158 | 31 | 20.00 | 28.00 | 7.73 | TBA | |

| BGTR2_2 | 663529 | 7846431 | 1136 | 663545 | 7846404 | 1136 | 151 | 32 | NSI | ||||

| BGTR2_3 | 663509 | 7846417 | 1136 | 663528 | 7846385 | 1135 | 151 | 38 | |||||

| T1 | PLWTR1 | 662335 | 7845815 | 1127 | 662377 | 7845739 | 1129 | 151 | 108 | 19.00 | 20.00 | 0.97 | TBA |

| 28.00 | 32.00 | 3.86 | |||||||||||

| 34.00 | 35.00 | 0.97 | |||||||||||

| 59.00 | 60.00 | 0.97 | |||||||||||

| 86.00 | 87.00 | 0.97 | |||||||||||

| PLWTR2 | 662262 | 7845779 | 1127 | 662309 | 7845694 | 1128 | 152 | 98 | 6.00 | 8.00 | 1.93 | ||

| 71.00 | 72.00 | 0.97 | |||||||||||

| 84.00 | 85.00 | 0.97 | |||||||||||

| PLVTR3 | 662221 | 7845788 | 1124 | 662290 | 7845660 | 1127 | 151 | 147 | 108.00 | 109.00 | 0.97 | ||

| PLVTR4 | 662181 | 7845746 | 1124 | 662238 | 7845631 | 1126 | 153 | 134 | NSI | ||||

| PLVTR5 | 662132 | 7845708 | 1123 | 662196 | 7845608 | 1125 | 147 | 119 | |||||

| PLVTR5EXT | 662045 | 7845842 | 1124 | 662132 | 7845708 | 1122 | 147 | 161 | |||||

| PLVTR8 | 662677 | 7845977 | 1132 | 662712 | 7845881 | 1134 | 151 | 104 | 4.00 | 6.00 | 1.93 | TBA | |

| 9.00 | 10.00 | 0.97 | |||||||||||

| 17.00 | 18.00 | 0.97 | |||||||||||

| 23.00 | 24.00 | 0.97 | |||||||||||

| 29.00 | 30.00 | 0.97 | |||||||||||

| 44.00 | 45.00 | 0.97 | |||||||||||

| 46.00 | 47.00 | 0.97 | |||||||||||

| 71.00 | 72.00 | 0.97 | |||||||||||

| 88.00 | 89.00 | 0.97 | |||||||||||

| PLVTR12 | 662505 | 7845826 | 1129 | 662542 | 7841751 | 1131 | 153 | 85 | 19.00 | 20.00 | 0.97 | ||

| 31.00 | 32.00 | 0.97 | |||||||||||

| 44.00 | 45.00 | 0.97 | |||||||||||

| PLVTR13 | 662699 | 7845989 | 1133 | 662731 | 7845897 | 1135 | 153 | 95 | 8.00 | 14.00 | 5.80 | ||

| 68.00 | 69.00 | 0.97 | |||||||||||

| Pluvious 4 | PL4TR2 | 662730 | 7846022 | 1133 | 662741 | 7845994 | 1132 | 158 | 31 | 12.00 | 13.00 | 0.97 | |

| 15.00 | 22.00 | 6.76 | |||||||||||

| 28.00 | 29.00 | 0.97 | |||||||||||

| 30.00 | 31.00 | 0.97 | |||||||||||

| PL4TR1 | 662741 | 7846042 | 1134 | 662760 | 7846011 | 1135 | 149 | 36 | 20.00 | 21.00 | 0.97 | ||

| 25.00 | 28.00 | 2.90 | |||||||||||

| 28.00 | 32.00 | 3.86 | |||||||||||

| 33.00 | 36.00 | 2.90 | |||||||||||

| PL4TR2_1 | 662761 | 7845954 | 1135 | 662771 | 7845929 | 1135 | 157 | 28 | NSI | ||||

| Pluvious 5 | PL5TR1 | 662834 | 7846122 | 1136 | 662848 | 7846095 | 1136 | 153 | 31 | 11.00 | 24.00 | 12.56 | TBA |

| 30.00 | 31.00 | 0.97 | |||||||||||

| PL5TR1EXT | 662849 | 7846093 | 1136 | 662881 | 7846048 | 1138 | 140 | 54 | 44.00 | 45.00 | 0.97 | ||

| PL5TR1A | 662868 | 7846068 | 1138 | 662895 | 7846027 | 1138 | 147 | 49 | 0.00 | 2.00 | 1.93 | ||

| 5.00 | 6.00 | 0.97 | |||||||||||

| 21.00 | 26.00 | 4.83 | |||||||||||

| PL5TR2 | 662865 | 7846129 | 1136 | 662893 | 7846073 | 1138 | 154 | 63 | 0.00 | 1.00 | 0.97 | ||

| 7.00 | 19.00 | 11.59 | |||||||||||

| 26.00 | 27.00 | 0.97 | |||||||||||

| PLV5TR2EXT | 662893 | 7846072 | 1138 | 662908 | 7846050 | 1139 | 147 | 90 | 72.00 | 73.00 | 0.97 | ||

| 77.00 | 80.00 | 2.90 | |||||||||||

| 84.00 | 86.00 | 1.93 | |||||||||||

| PL5TR7 | 662960 | 7846205 | 1138 | 662973 | 7846182 | 1138 | 150 | 27 | 1.00 | 27.00 | 25.11 | ||

| Pluvious 123 | PLV123TR6 | 661909 | 7845767 | 1124 | 662031 | 7845575 | 1124 | 148 | 230 | 38.00 | 39.00 | 0.97 | |

| 88.00 | 89.00 | 0.97 | |||||||||||

| 95.00 | 96.00 | 0.97 | |||||||||||

| Shawl | SHETR1 | 664447 | 7847219 | 1148 | 664484 | 7847160 | 1151 | 157 | 69 | 2.00 | 3.00 | 0.97 | |

| 6.00 | 8.00 | 1.93 | |||||||||||

| 14.00 | 15.00 | 0.97 | |||||||||||

| 20.00 | 22.00 | 1.93 | |||||||||||

| 31.00 | 39.00 | 7.73 | |||||||||||

| 40.00 | 42.00 | 1.93 | |||||||||||

| 68.00 | 69.00 | 0.97 | |||||||||||

| Britwell | MTR28 | 664851 | 7845423 | 1148 | 665087 | 7845043 | 1169 | 148 | 452 | 35.00 | 36.00 | 0.97 | |

| 85.00 | 87.00 | 1.93 | |||||||||||

| 360.00 | 361.00 | 0.97 | |||||||||||

| Total Trenched To Date (m) | 12112 | ||||||||||||

Table 4: Trenching Results

| Diamond Drillholes Intercepts | ||||||||

| Holes Identifier |

Orebody Name |

Orebody Intersection |

Core Length (m) |

True width (m) |

Grade (g/t) |

Orebody Intersection depth from surface (m) |

E.O.H (m) | |

| From (m) |

To (m) |

|||||||

| JDD01 | JUPITER | 58.00 | 62.00 | 4.00 | 3.74 | 3.00 | 45.01 | 154.88 |

| 77.00 | 80.00 | 3.00 | 2.81 | 3.34 | 54.45 | |||

| JDD02 | 156.00 | 157.00 | 1.00 | 0.85 | 1.93 | 130.00 | 248.03 | |

| 163.00 | 164.00 | 1.00 | 0.85 | 1.20 | 135.00 | |||

| JDD03 | 69.73 | 70.50 | 0.77 | 0.74 | 0.77 | 55.00 | 295.88 | |

| 147.00 | 156.00 | 9.00 | 8.63 | 1.89 | 113.20 | |||

| 160.00 | 163.00 | 3.00 | 2.88 | 2.05 | 124.00 | |||

| 206.50 | 207.35 | 0.85 | 0.82 | 1.09 | 160.00 | |||

| JDD04 | 63.00 | 64.54 | 1.54 | 1.48 | 1.67 | 50.00 | 250.88 | |

| 81.00 | 82.00 | 1.00 | 0.96 | 1.76 | 60.00 | |||

| 88.00 | 93.00 | 5.00 | 4.80 | 1.01 | 70.00 | |||

| 142.00 | 143.00 | 1.00 | 0.96 | 0.96 | 103.00 | |||

| 146.00 | 150.00 | 4.00 | 3.84 | 0.71 | 106.00 | |||

| 152.00 | 153.00 | 1.00 | 0.96 | 0.82 | 107.00 | |||

| JDD05 | 43.82 | 52.00 | 8.18 | 6.95 | 0.99 | 32.00 | 79.68 | |

| 60.00 | 68.00 | 8.00 | 6.80 | 2.50 | 45.00 | |||

| JDD06 | 66.00 | 67.00 | 1.00 | 0.84 | 1.01 | 55.12 | 274.98 | |

| JDD07 | 56.00 | 57.00 | 1.00 | 0.87 | 2.23 | 40.11 | 199.88 | |

| 61.00 | 64.00 | 3.00 | 2.61 | 3.73 | 45.23 | |||

| 66.00 | 69.80 | 3.80 | 3.31 | 1.87 | 48.30 | |||

| 95.00 | 96.00 | 1.00 | 0.87 | 0.75 | 68.00 | |||

| JDD08 | 39.00 | 40.00 | 1.00 | 0.86 | 2.75 | 27.58 | 199.68 | |

| 63.00 | 77.00 | 14.00 | 12.04 | 3.20 | 44.55 | |||

| JDDD10 | 12.60 | 15.00 | 2.40 | 2.25 | 0.56 | 23.48 | 76.88 | |

| 21.00 | 21.37 | 0.37 | 0.35 | 0.61 | 29.21 | |||

| 39.00 | 40.41 | 1.41 | 1.32 | 1.03 | 43.76 | |||

| BMGDD01 | BOOMGATE | NSI | 103.98 | |||||

| BMGDD02 | 67.00 | 70.00 | 3.00 | 2.81 | 2.26 | 50.00 | 139.93 | |

| 72.00 | 73.00 | 1.00 | 0.94 | 2.44 | 52.00 | |||

| 91.00 | 92.00 | 1.00 | 0.94 | 0.81 | 67.00 | |||

| 94.00 | 95.00 | 1.00 | 0.94 | 0.65 | 70.00 | |||

| 96.60 | 98.00 | 1.40 | 1.31 | 2.36 | 71.00 | |||

| 106.00 | 109.00 | 3.00 | 2.81 | 3.84 | 78.00 | |||

| 132.00 | 133.00 | 1.00 | 0.94 | 1.07 | 96.00 | |||

| PLVDD01 | PLUVIOUS 5 | 59.00 | 60.00 | 1.00 | 0.87 | 1.11 | 60.81 | 169.98 |

| 74.00 | 82.00 | 8.00 | 6.94 | 4.00 | 57.51 | |||

| PLVDD02 | PLUVIOUS 4 | 64.00 | 66.00 | 2.00 | 1.75 | 4.04 | 50.43 | 148.98 |

| 74.00 | 74.90 | 0.90 | 0.79 | 2.80 | 88.31 | |||

| PLVDD03 | PLUVIOUS 1,2&3 | 75.00 | 81.00 | 6.00 | 5.61 | 1.58 | 53.03 | 154.98 |

| 83.00 | 84.00 | 1.00 | 0.94 | 1.44 | 58.69 | |||

| 94.00 | 95.00 | 1.00 | 0.94 | 1.68 | 66.46 | |||

| 104.00 | 106.00 | 2.00 | 1.87 | 0.95 | 73.54 | |||

| PLVDD04 | 137.00 | 142.00 | 5.00 | 4.80 | 3.31 | 114.90 | 247.98 | |

| PLVDD05 | 89.00 | 90.00 | 1.00 | 0.97 | 1.07 | 72.15 | 97.98 | |

| Reverse Circulation Drilling Intercepts | ||||||||

| Holes Identifier | Orebody Name | Orebody Intersection | Core Length (m) | True width(m) | Grade(g/t) | Orebody Intersection depth from surface(m) | E.O.H (m) | |

| From (m) | To (m) | |||||||

| SHRC01 | SHAWL | 56.00 | 57.00 | 1.00 | 0.85 | 1.32 | 47.00 | 153 |

| 60.00 | 61.00 | 1.00 | 0.85 | 1.10 | 50.30 | |||

| 62.00 | 64.00 | 2.00 | 1.70 | 0.66 | 52.00 | |||

| 109.00 | 112.00 | 3.00 | 2.55 | 5.03 | 91.42 | |||

| 124.00 | 127.00 | 3.00 | 2.55 | 4.21 | 100.64 | |||

| 131.00 | 138.00 | 7.00 | 5.95 | 1.68 | 109.87 | |||

| SHRC02 | 44.00 | 46.00 | 2.00 | 1.70 | 1.81 | 38.48 | 112 | |

| 57.00 | 73.00 | 16.00 | 13.60 | 1.75 | 49.85 | |||

| 97.00 | 100.00 | 3.00 | 2.55 | 0.67 | 84.84 | |||

| JPRC01 | JUPITER | 72.00 | 74.00 | 2.00 | 1.62 | 0.66 | 60.38 | 110 |

| 81.00 | 93.00 | 12.00 | 9.72 | 6.36 | 67.93 | |||

| JPRC02 | 79.00 | 80.00 | 1.00 | 0.81 | 0.73 | 66.25 | 140 | |

| 108.00 | 112.00 | 4.00 | 3.24 | 3.21 | 90.58 | |||

| JPRC04 | NSI | 120 | ||||||

| JPRC05 | 88.00 | 101.00 | 13.00 | 10.53 | 5.17 | 76.21 | 160 | |

| BMGRC01 | BOOMGATE | 55.00 | 56.00 | 1.00 | 0.75 | 3.93 | 47.63 | 97 |

| 61.00 | 63.00 | 2.00 | 1.54 | 2.64 | 52.83 | |||

| 66.00 | 68.00 | 2.00 | 1.62 | 1.02 | 57.16 | |||

| PLVRC01 | PLUVIOUS 5 | 63.00 | 70.00 | 7.00 | 5.67 | 3.02 | 50.97 | 110 |

| PLVRC06 | PLUVIOUS 1,2&3 | 64.00 | 71.00 | 7 | 6.62 | 3.27 | 53.68 | 150 |

| 81.00 | 83.00 | 2 | 1.89 | 1.56 | 67.76 | |||

| 127.00 | 129.00 | 2 | 1.89 | 1.12 | 105.18 | |||

| PLVRC07 | NSI | 120 | ||||||

| BRRC01_0 | BRITWELL | 62.00 | 66.00 | 4.00 | 2.36 | 0.53 | 50.80 | 92 |

| 75.00 | 79.00 | 4.00 | 2.36 | 1.67 | 61.84 | |||

| MPZRC01 | MPUDZI | 2.00 | 8.00 | 6.00 | 3.90 | 3.12 | 1.00 | 35 |

| 14.00 | 16.00 | 2.00 | 1.30 | 2.56 | 11.00 | |||

| 18.00 | 19.00 | 1.00 | 0.65 | 3.33 | 13.00 | |||

| MPZRC02 | 3.00 | 5.00 | 2.00 | 1.93 | 0.75 | 3.00 | 55 | |

| 12.00 | 16.00 | 4.00 | 3.86 | 10.95 | 8.00 | |||

| 36.00 | 39.00 | 3.00 | 2.89 | 2.83 | 25.00 | |||

| MPZRC03 | 6.00 | 12.00 | 6.00 | 5.11 | 2.58 | 6.64 | 40 | |

| 15.00 | 17.00 | 2.00 | 1.70 | 1.87 | 9.07 | |||

| MPZRC04 | NSI | 80 | ||||||

| MPZRC05 | NSI | 29 | ||||||

| MPZRC06 | NSI | 40 | ||||||

| MPZRC07 | 47.00 | 48.00 | 1.00 | 0.78 | 0.75 | 32.18 | 65 | |

| MPZRC08 | 36.00 | 39.00 | 3.00 | 2.86 | 9.96 | 30.23 | 88 | |

| MPRC22 | 5 | 7 | 2.00 | 1.62 | 4.29 | 3.83 | 115 | |

| 21 | 23 | 2.00 | 1.62 | 2.28 | 16.09 | |||

Table 5: RC and DD Drilling Results

| Diamond Drillhole Collars | ||||||

| Hole Identifier | Azimuth (°) | Dip (°) | Drilled Length (m) | UTM Easting (m) | UTM Northing (m) | UTM Elevation (m) |

| JDD01 | 349 | 44 | 154.88 | 663722 | 7846505 | 1134 |

| JDD02 | 354 | 56 | 248.03 | 664193 | 7846797 | 1145 |

| JDD03 | 354 | 51 | 295.88 | 664165 | 7846739 | 1145 |

| JDD04 | 337 | 50 | 250.88 | 664125 | 7846715 | 1142 |

| JDD05 | 340 | 47 | 79.68 | 664010 | 7846678 | 1137 |

| JDD06 | 340 | 57 | 274.98 | 663920 | 7846618 | 1134 |

| JDD07 | 339 | 46 | 199.88 | 663880 | 7846590 | 1135 |

| JDD08 | 336 | 43 | 199.68 | 663824 | 7846552 | 1135 |

| JDD09 | 340 | 47 | 68.72 | 664195 | 7846900 | 1147 |

| JDD10 | 350 | 52 | 76.88 | 663768 | 7846572 | 1122 |

| PLVDD01 | 332 | 51 | 169.98 | 663160 | 7846143 | 1138 |

| PLVDD02 | 335 | 52 | 148.98 | 662798 | 7845936 | 1137 |

| PLVDD03 | 337 | 44 | 154.98 | 662606 | 7845791 | 1131 |

| PLVDD04 | 340 | 57 | 247.98 | 662571 | 7845686 | 1131 |

| PLVDD05 | 350 | 55 | 97.98 | 662471 | 7845779 | 1130 |

| PLVDD06 | 330 | 57 | 70.88 | 663140 | 7846180 | 1139 |

| BMGDD01 | 337 | 50 | 103.98 | 663555 | 7846434 | 1136 |

| BMGDD02 | 330 | 46 | 139.93 | 663528 | 7846350 | 1134 |

| SHDD01 | 340 | 47 | 97.88 | 664336 | 7847082 | 1146 |

| BRDD01_0 | 332 | 52 | 158.03 | 664726 | 7845022 | 1166 |

| BRDD03_0 | 325 | 57 | 172.88 | 664454 | 7844838 | 1166 |

| HDD01 | 334 | 45 | 91.88 | 664988 | 7843497 | 1140 |

| HDD02 | 330 | 45 | 112.88 | 665208 | 7843548 | 1142 |

| JPT11TW | 341 | 56 | 112.00 | 663442 | 7846307 | 1135 |

| JPT13TW | 328 | 48 | 214.98 | 662661 | 7845717 | 1132 |

| DHJ7_2TW | 335 | 71 | 95.03 | 664057 | 7846690 | 1139 |

| Reverse Circulation Drillhole collars | ||||||

| Hole Identifier | Azimuth (°) | Dip (°) | Drilled Length (m) | UTM Easting (m) | UTM Northing (m) | UTM Elevation (m) |

| SHRC01 | 321 | 57 | 153 | 664332 | 7847065 | 1148 |

| SHRC02 | 331 | 62 | 112 | 664399 | 7847115 | 1149 |

| JPRC01 | 340 | 57 | 110 | 664200 | 7846886 | 1147 |

| JPRC02 | 341 | 57 | 140 | 664175 | 7846847 | 1145 |

| JPRC04 | 349 | 60 | 120 | 663884 | 7846717 | 1135 |

| JPRC05 | 344 | 52 | 101 | 663785 | 7846502 | 1134 |

| BMGRC01 | 336 | 59 | 97 | 663460 | 7846364 | 1136 |

| PLVRC01 | 335 | 54 | 110 | 663267 | 7846237 | 1138 |

| PLVRC05 | 336 | 53 | 160 | 662678 | 7845850 | 1133 |

| PLVRC06 | 340 | 57 | 150 | 662484 | 7845743 | 1130 |

| PLVRC07 | 340 | 56 | 120 | 662430 | 7845734 | 1129 |

| PLVRC10 | 327 | 50 | 70 | 662417 | 7845771 | 1129 |

| MPZRC01 | 326 | 50 | 35 | 666367 | 7845590 | 1185 |

| MPZRC02 | 330 | 50 | 55 | 666379 | 7845571 | 1187 |

| MPZRC03 | 329 | 51 | 40 | 666073 | 7845420 | 1166 |

| MPZRC04 | 330 | 52 | 80 | 665928 | 7845276 | 1183 |

| MPZRC05 | 329 | 51 | 29 | 665855 | 7845396 | 1176 |

| MPZRC06 | 153 | 54 | 40 | 666279 | 7845474 | 1174 |

| MPZRC07 | 331 | 49 | 65 | 665903 | 7845317 | 1186 |

| MPZRC08 | 329 | 47 | 88 | 666004 | 7845341 | 1179 |

| MPZRC09 | 327 | 50 | 60 | 666088 | 7845397 | 1166 |

| MPZRC17 | 327 | 50 | 91 | 666314 | 7845671 | 1176 |

| MPZRC17_3 | 327 | 50 | 146 | 666421 | 7845505 | 1188 |

| MPZRC19_1 | 327 | 50 | 108 | 666507 | 7845542 | 1198 |

| MPZRC22 | 154 | 48 | 115 | 666197 | 7845620 | 1168 |

| MPZRC23 | 327 | 50 | 65 | 666534 | 7845687 | 1196 |

| MPZRC24 | 327 | 50 | 67 | 665738 | 7845587 | 1155 |

| BRRC01_0 | 331 | 55 | 92 | 664701 | 7845064 | 1166 |

| BRRC2_0 | 331 | 56 | 108 | 664541 | 7844976 | 1170 |

| BRRC3_0 | 326 | 56 | 115 | 664426 | 7844878 | 1165 |

| FSKRC01 | 340 | 50 | 41 | 665198 | 7844904 | 1162 |

| TRRC01 | 340 | 50 | 50 | 666066 | 7844148 | 1143 |

| TRRC02 | 340 | 50 | 122 | 665990 | 7844038 | 1150 |

| TRRC03 | 340 | 50 | 145 | 665892 | 7843981 | 1150 |

| HDRC01 | 332 | 50 | 50 | 664825 | 7843416 | 1139 |

| HDRC02 | 325 | 47 | 120 | 665171 | 7843599 | 1144 |

Table 6: RC and DD Drilling Collar and Survey Information

Glossary

| Term | Definition |

| Aero-magnetics | A geophysical exploration method in which a magnetometer, often mounted on an aircraft, is used to measure variations in the Earth’s magnetic field over a specific area. |

| Assay | A process of analysing a sample to determine its composition, particularly to measure the concentration of metal (e.g., gold) within it. |

| Azimuth | The angle between the north direction and the projection of the line to a point, typically used in mapping and surveying. |

| Blank (Sample) | A type of control sample with a known low concentration of analyte, used in quality assurance to detect contamination. |

| Bottle Roll Assay | A test method for determining gold content by using a rotating bottle and a leaching solution, often used on-site in laboratories. |

| Brownfield Exploration | Exploration activities conducted near or around an existing mine, contrasting with greenfield, which targets unexplored areas. |

| Carbonate | Refers to a group of minerals containing the carbonate ion (CO₃²⁻). In exploration, carbonate alteration can signal the presence of hydrothermal systems, where hot fluids have deposited metals in the surrounding rock. |

| Certified Reference Material (CRM) | A material or substance with a certified composition used to ensure the accuracy and consistency of analytical results. |

| Composite Sample | A sample made by combining individual samples from various sections to create a single, representative sample for analysis. |

| Core Length | The total measured length of the sample core obtained from drilling, often used to analyse mineral composition and structure. |

| Cut-off Grade | The minimum grade or concentration of mineral that must be met for material to be considered viable for processing. |

| Diamond Drilling (DD) | A drilling technique using a diamond drill bit to retrieve core samples for geological assessment, commonly used for detailed exploration. |

| Down-the-Hole Survey | A measurement process to check the angle and path of a borehole as it is drilled, ensuring it follows the planned direction. |

| Duplicate Sample | A second sample taken from the same source to verify the accuracy and reproducibility of assay results. |

| End of Hole (E.O.H.) | The final depth reached in a borehole or drilling operation. |

| Fire Assay | A traditional method to measure precious metal content by heating and melting the sample, allowing separation of metal content for analysis. |

| Grade (g/t) | The concentration of precious metal, typically measured in grams per ton (g/t) of ore, used as a quality indicator of mineral deposits. |

| Greenfield Exploration | Exploration of new, previously untouched areas with no prior mining activity to discover new mineral deposits. |

| Lab Pulp Repeat (LPR) | A quality assurance process where lab samples are pulverized and analysed to ensure consistent assay results. |

| Magnetite | An iron oxide mineral with the chemical formula Fe₃O₄ and is known for its strong magnetic properties. |

| Mineralised Zone | A section of rock where minerals, especially economically valuable ones, are concentrated. |

| Motapa Exploration Program | An exploration project focused on the Motapa area, involving trenching, drilling, and geophysical surveys to identify and quantify mineral deposits. |

| Pyrite | An iron sulphide mineral with the chemical formula FeS₂. In mining exploration, pyrite is significant as it often forms in the same hydrothermal environments that produce valuable minerals like gold, copper, and silver. |

| Quality Assurance / Quality Control (QA/QC) | Procedures in place to ensure the reliability and accuracy of testing and analytical methods in sampling and assay results. |

| Reverse Circulation (RC) Drilling | A method of drilling that uses compressed air to bring rock cuttings to the surface, allowing sampling without retrieving a core. |

| Riffle Splitter | A device used in sampling to divide material into equal portions, helping obtain a representative sample. |

| Sericite | A fine-grained, mica-like mineral, typically a variety of muscovite or illite, that forms through the alteration of feldspar and other minerals. |

| Shear Zone | A region of rock that has been deformed by shear forces, often associated with mineral deposits due to increased permeability and mineralization potential. |

| Shear Zone | A region of rock where intense deformation has occurred due to the application of shear stress, typically deep within the Earth’s crust. This deformation often creates fractures, faults, and altered rock textures, making these zones more permeable and, as a result, more conducive to mineral deposits. |

| Silica | A mineral compound made of silicon and oxygen (SiO₂). In mining exploration, silica alteration is often a good indicator of mineralization, especially in hydrothermal systems. |

| Trench Sampling | A method of sampling in exploration where trenches are dug to expose bedrock, allowing geological mapping and sampling. |

| True Width | The actual thickness of a mineralized zone, as opposed to the core length measured in drilling, adjusted for the angle of drilling. |

Cautionary Note Concerning Forward-Looking Information

Information and statements contained in this news release that are not historical facts are “forward-looking information” within the meaning of applicable securities legislation that involve risks and uncertainties relating, but not limited, to Caledonia’s current expectations, intentions, plans, and beliefs. Forward-looking information can often be identified by forward-looking words such as “anticipate”, “believe”, “expect”, “goal”, “plan”, “target”, “intend”, “estimate”, “could”, “should”, “may” and “will” or the negative of these terms or similar words suggesting future outcomes, or other expectations, beliefs, plans, objectives, assumptions, intentions or statements about future events or performance. Examples of forward-looking information in this news release include: our plans and timing regarding further exploration and drilling and development at Motapa. This forward-looking information is based, in part, on assumptions and factors that may change or prove to be incorrect, thus causing actual results, performance or achievements to be materially different from those expressed or implied by forward-looking information. Such factors and assumptions include, but are not limited to: failure to establish estimated resources and reserves, the grade and recovery of ore which is mined varying from estimates, success of future exploration and drilling programs, reliability of drilling, sampling and assay data, assumptions regarding the representativeness of mineralization being inaccurate, success of planned metallurgical test-work, capital and operating costs varying significantly from estimates, delays in obtaining or failures to obtain required governmental, environmental or other project approvals, inflation, changes in exchange rates, fluctuations in commodity prices, delays in the development of projects and other factors.

Security holders, potential security holders and other prospective investors should be aware that these statements are subject to known and unknown risks, uncertainties and other factors that could cause actual results to differ materially from those suggested by the forward-looking statements. Such factors include, but are not limited to: risks relating to estimates of mineral reserves and mineral resources proving to be inaccurate, fluctuations in gold price, risks and hazards associated with the business of mineral exploration, development and mining, risks relating to the credit worthiness or financial condition of suppliers, refiners and other parties with whom the Company does business; inadequate insurance, or inability to obtain insurance, to cover these risks and hazards, employee relations; relationships with and claims by local communities and indigenous populations; political risk; risks related to natural disasters, terrorism, civil unrest, public health concerns (including health epidemics or outbreaks of communicable diseases such as the coronavirus (COVID-19)); availability and increasing costs associated with mining inputs and labour; the speculative nature of mineral exploration and development, including the risks of obtaining or maintaining necessary licenses and permits, diminishing quantities or grades of mineral reserves as mining occurs; global financial condition, the actual results of current exploration activities, changes to conclusions of economic evaluations, and changes in project parameters to deal with unanticipated economic or other factors, risks of increased capital and operating costs, environmental, safety or regulatory risks, expropriation, the Company’s title to properties including ownership thereof, increased competition in the mining industry for properties, equipment, qualified personnel and their costs, risks relating to the uncertainty of timing of events including targeted production rate increase and currency fluctuations. Security holders, potential security holders and other prospective investors are cautioned not to place undue reliance on forward-looking information. By its nature, forward-looking information involves numerous assumptions, inherent risks and uncertainties, both general and specific, that contribute to the possibility that the predictions, forecasts, projections and various future events will not occur. Caledonia undertakes no obligation to update publicly or otherwise revise any forward-looking information whether as a result of new information, future events or other such factors which affect this information, except as required by law.

This news release is not an offer of the shares of Caledonia for sale in the United States or elsewhere. This news release shall not constitute an offer to sell or the solicitation of an offer to buy, nor shall there be any sale of the shares of Caledonia, in any province, state or jurisdiction in which such offer, solicitation or sale would be unlawful prior to registration or qualification under the securities laws of such province, state or jurisdiction.

Photos accompanying this announcement is available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/8e815077-9185-4dee-af8e-0acaf9012ba3

https://www.globenewswire.com/NewsRoom/AttachmentNg/8d927cdc-dec3-48a3-943d-65a1011f0457

https://www.globenewswire.com/NewsRoom/AttachmentNg/553b2acc-7fec-4d1b-951d-cdd88a9c1c05

https://www.globenewswire.com/NewsRoom/AttachmentNg/a53ea857-78c6-4472-920b-6ada456f6ae6

https://www.globenewswire.com/NewsRoom/AttachmentNg/87899953-62ec-4390-909e-9a5bd88f496a

https://www.globenewswire.com/NewsRoom/AttachmentNg/68bdc248-734e-4780-bb2e-84fe6c57c3f1